Mortar sprayers combine powerful pumps with precision spray guns to move and apply mortar exactly where you need it – whether you’re doing shotcrete, stucco, fireproofing, or repair work. No more buckets, no more troweling everything by hand, and no more crews getting worn out before lunch.

We’ve been building mortar pumps and spray systems since 1968. Our equipment handles everything from fine plaster finishes to heavy-bodied shotcrete with aggregates and fiber reinforcement. If you can mix it, we can help you spray it.

Quikspray's Mortar Sprayers and Systems

Multi Air Jet

The Workhorse for Heavy Mortar Applications

This is what you grab when you’re spraying heavy-bodied coatings with aggregates or fiber reinforcement. The multi-jet design uses several air streams to atomize and propel material, giving you consistent coverage even with chunky mixes.

Single Air Jet

Precision Application for Finer Finishes

When you need a smoother, more controlled spray pattern – think finish coats, waterproofing, or decorative plasters – the single jet gun gives you better atomization and less overspray.

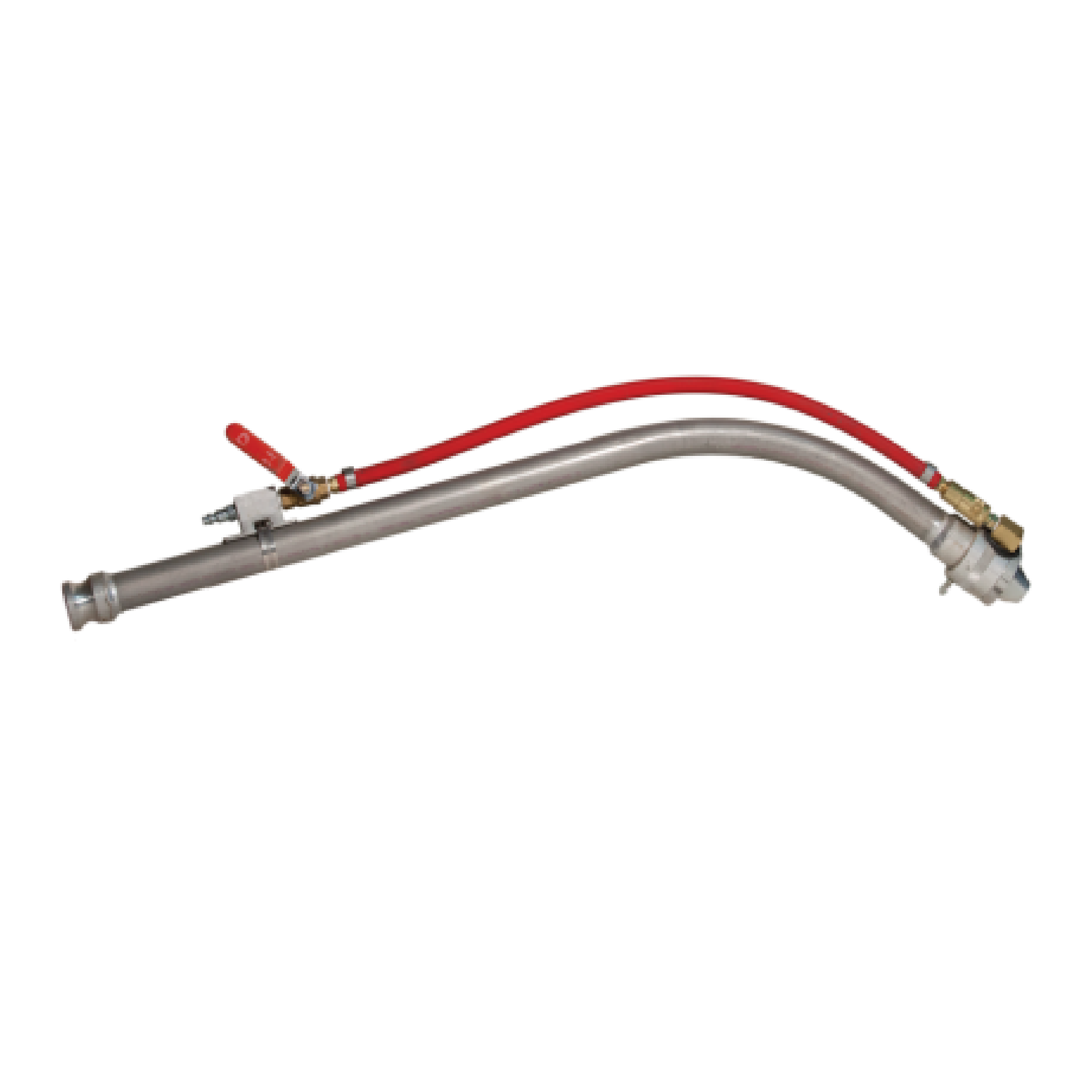

Shotcrete/Stucco Gun (8-Jet Design)

Fast Material Placement for Production Work

The 8-jet configuration is specifically designed for applications where you need to build thickness quickly. Whether you’re shooting pool shells, retaining walls, or heavy stucco coats, this gun moves material fast.

Carrousel® Heavy Duty Grout Pump

Built for Continuous Operation with Thick Materials

When you’re pumping heavily-filled materials all day – think thick grouts, portland cement mixtures, or aggregated repair mortars – this is the pump that keeps working. The heavy-duty design handles materials that would choke standard pumps.

Carrousel® Pump

The Industry Standard for Mortar Pumping

The Carrousel pump uses peristaltic action – basically the same squeeze principle as your digestive system. Rollers rotate against a rubber tube, pushing material through without it touching any mechanical parts. This means you can pump abrasive materials, aggregates, and fiber-reinforced mortars without tearing up expensive pump components.

200 Grout Plant™

High-Volume Production for Big Jobs

Large commercial projects need equipment that can keep up with crew demand. The Grout Plant delivers consistent material flow for crews working on multiple surfaces simultaneously.

Why Mortar Spraying Beats Manual Application

Speed that actually matters

Hand application is slow. Really slow. A two-person crew with a mortar sprayer can often outproduce a six-person crew working manually. That’s not marketing hype – that’s what we hear from contractors who’ve made the switch.

On vertical applications like stucco or shotcrete, spraying eliminates the physical strain of lifting and troweling heavy material overhead. Your crew stays productive longer, and quality stays consistent throughout the day.

Better Material Adhesion

Sprayed mortar has better compaction and adhesion than hand-applied material, especially on vertical and overhead surfaces. The velocity of application forces material into substrate irregularities and around reinforcement, creating better mechanical bond.

For shotcrete applications, proper spray velocity is critical for achieving specified compressive strength. You can only get that with mortar sprayers.

Consistent coverage and thickness

With hand application, thickness varies based on worker technique and fatigue level. Spraying gives you consistent coverage across the entire surface, which matters for both structural applications and finished appearance.

Less Material Waste

Yeah, spraying creates some overspray. But compare that to the material that falls off during hand application, the mortar that dries out in buckets, and the inconsistent coverage that requires rework. Most contractors find they actually waste less material once they dial in their spray technique.

Common Applications for Mortar Sprayers

Stucco and EIFS Systems

Multi-Coat Stucco Applications

The Carrousel pump paired with an 8-jet gun handles everything from scratch coats to finish applications. Consistent material delivery means uniform thickness and better crack resistance.

EIFS Base Coats

Embedding mesh in base coat is way easier when you can spray material, set mesh, and spray again. Hand-troweling this process takes forever and often traps air behind the mesh.

Shotcrete Applications

Pool Shells and Water Features

Sprayed concrete for pools needs specific compaction for watertightness. Our pump and gun systems provide the velocity and volume needed for proper placement.

Structural Shotcrete

Retaining walls, slope stabilization, and structural repairs require specific mix designs and application techniques. The Carrousel pump handles fiber-reinforced mixes without clogging.

Repair & Restoration

Vertical and Overhead Repairs

Getting repair mortar to stay in place on vertical surfaces or overhead is tough. Spraying provides the velocity needed for proper adhesion without formwork

Large-Area Resurfacing

When you're resurfacing entire walls or parking structures, spraying is the only practical method for maintaining schedule and quality.

What Sets Quikspray Systems Apart

Peristaltic Design Advantages

Most mortar pumps use progressive cavity or piston designs that wear out fast with abrasive materials. Our peristaltic system isolates the material from mechanical components, dramatically extending service life.

Tested with Real Materials

We don't just test with water and call it good. Send us your actual mix design and we'll test it for free - you get a written report and video showing exactly how it performs. No surprises on the job site.

Parts and Support

We stock parts for pumps we built in the 1970s. When you invest in Quikspray equipment, you're not on your own when something eventually needs service.

Get Started with Mortar Spraying

Never sprayed before? Most contractors pick it up quickly, but there is a learning curve. Start with smaller areas to get comfortable with material flow rates and spray patterns. We’re happy to provide application guidance based on your specific materials.

Questions about which system fits your work? Call us at (419) 732-2611. We’ll discuss your typical applications, material types, and volume requirements to recommend the right pump and gun combination.

Want to test your materials first? Send us samples and we’ll show you exactly how they perform with our equipment. Free testing means no expensive mistakes.

Take the Next step

After 55+ years of helping contractors spray mortar, we’ve learned that the right equipment makes all the difference between frustrated crews and profitable projects. Let us help you figure out what works for your jobs.