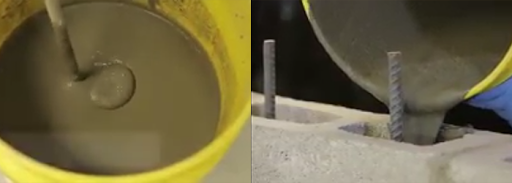

No two grout applications are going to be the same because there’s such a wide variety of grout types, mixing processes, grout pumps, and applications. But using trial-and-error with grout mixing and pumping isn’t the best method, as you could end up wasting your grout or impeding your project. Having a few basic mixing and pumping tips in your back pocket can help you achieve your desired finished product.

Tips for Mixing and Pumping Grout

The following consideration suggestions can help ensure a successful grout application using a grout pump.

Types of Grout

There are different types of grout and grout mixes, and some aren’t as suitable for pumping as others. Generally, thicker grouts don’t work as well in pumping applications as more thinly-mixed grouts, simply because their consistency won’t allow them to move through the pump as easily.

Similarly, grouts that are too wet may also not work well. It’s important to be careful to follow mixing instructions for any grout, especially if there are separate instructions for preparing the grout for a pump. And, make sure you’re using the right type of grout — cementitious or epoxy — for your particular pump.

Check out Quikspray Grout Mixers!

Grout Setting Time

Many grouts set quickly once they’re mixed, making it crucial to use them as soon as possible in your pump after mixing. Take this into account when you’re mixing your grout. Mix only enough that you can use within a few minutes in your pump. Then, continue to make batches of grout as needed to complete your project.

Again, the type of grout makes a difference. Epoxy grout tends to set more quickly than cementitious grout, so it works better when you mix and apply it in stages, allowing each batch to settle before applying another grout layer.

Grout Flow

The type and consistency of your grout will affect its flow, or its ability to flow through your grout pump. It’s necessary to determine the type of grout and flow you need for your particular application.

To fill in spaces with narrow cracks or openings, for instance, a cementitious grout will work best. Its high flow rate allows it to maneuver into smaller areas quickly when pumped. In contrast, epoxy grout doesn’t flow as well, which isn’t ideal for some pumps and applications.

Pump Types

Be thorough when researching different grout pumps for your project, as they’re not a one-size-fits-all tool. Rather, there are some grout pumps that work better for different applications and types of grout.

Quikspray carries a variety of grout pumps in different styles, sizes, capacities, and capabilities, ensuring that you find one that meets the needs of your project.

Pumping Distance

Pumping grout usually works best when you aren’t a significant distance away from your target. Although many pumps are designed to allow for long distance pumping, you can ensure a more direct and precise application with shorter distances.

Set up your workspace beforehand to allow for a short pumping distance, if possible. If long distance pumping is a must, make sure that your grout pump is the right one for the job.

Pumping Procedures

Cleanliness of your pump is the key to a successful grout application. Your pump should be cleaned outside and inside before and after each use. Make sure all internal components are clean and free of buildup to avoid interfering with your grout’s chemical makeup and flow.

While pumping, be sure to continuously check the operation of your grout pump. It’s possible for the pump to get clogged during the process, but remaining vigilant to signs of problems can help you avoid issues. Listen for sounds of straining from the pump or signs that the grout flow is slowing down. If this happens, stop the pump, clean it out, and mix a new batch of grout.

Quikspray is your go-to resource for grouting and grout pumps. Our lineup of grout pumps allows for versatile grout applications. We’ll even help you figure out which pump you need based on the details of your project. Contact us at 419-732-2611 for assistance.