Industrial applications require specific types of grout that are designed to handle heavy loads to create a strong, reliable bond. Cementitious and epoxy are the primary types of grouts you’ll see mentioned in industrial applications.

Both types of grout are incredibly strong, but each has its pros and cons in industrial applications. You can determine which type of grout is best for your project based on its ease of use, strengths, drawbacks, and restrictions.

Keep reading to learn the difference between cementitious and epoxy grout!

Whichever grout you decide to use, Quikspray, Inc. has a grout mixer that can help you get the job done. Contact us today to learn more about our grout mixers, tell us about your needs, and get expert recommendations for your product match.

Cementitious Grout

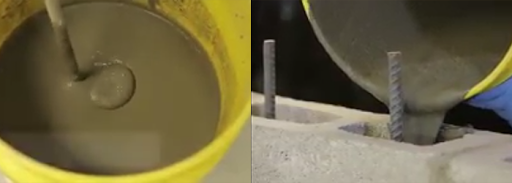

Cementitious grout has cement as its binder and comes in powder form. To create the grout, you add water and mix the components together. Cementitious grouts have a maximum water content you shouldn’t exceed to ensure that the grout holds together and bonds properly to a surface.

Applications and Advantages of Cementitious Grout

Cementitious grout has an average ideal application temperature range of between 50℉ and 90℉. However, many special formulas can handle temperatures much higher or lower than this range, making them ideal for working in cold or hot temperatures.

Cementitious grout can also flow farther than epoxy grout, allowing it to make its way through tight spaces and into minuscule cracks deep within a surface. Industrial applications that typically use cementitious grout include grouting precast foundations that have already been pre-stressed and constructing baseplates.

Drawbacks of Cementitious Grout

If you’re not using a special formula that allows for application in colder or hotter temperatures, cementitious grout is particular in its application needs. You’ll need to stay within the ideal temperature window for the grout to cure properly.

Cementitious grout also cannot come into contact with water after you’ve mixed it to its proper consistency. A wet surface can change the chemistry and physics of the grout, causing it to become unusable.

Although cementitious grout is strong enough to support many industrial applications, it cannot accommodate the needs of early high strength applications like epoxy grout can.

Epoxy Grout

Unlike cementitious grout that contains exactly one component until mixed, epoxy grout includes resin, a hardener, and an aggregate, like sand or ground stone. To create an epoxy grout, you mix together each component rather than add water like cementitious grout.

Applications and Advantages of Epoxy Grout

Epoxy grout has several advantages over cement grout that makes it an ideal option for many industrial applications. One of its most significant benefits is its ability to work well in early high strength applications, meaning that it’s best to use when you need it to set rapidly.

Epoxy is also resistant to oil and chemicals, making it an excellent choice to use in applications where contact with chemicals is inevitable. The grout won’t shrink, expand, warp, or corrode when it meets chemicals or oil.

Due to its high strength, epoxy may also be the best option as a reinforcement to concrete that needs repairs. Use epoxy grout to fill in cracks or add support to concrete that’s already in place.

Drawbacks of Epoxy Grout

Epoxy grout sets more rapidly than cementitious grout, so you’ll need to work with it quickly to ensure it ’s placed properly. It may require work in stages to avoid uneven application.

Epoxy also doesn’t flow as easily as cementitious grout. It may not find its way to fill narrow crevices or offer support to baseplates or machinery like cementitious grout’s high flow rate allows it to.

Choosing the Right Industrial Grout

The right industrial grout for your job depends on your application’s needs, like the temperature you’ll be working on and early strength requirements. Consider the advantages and drawbacks of each to determine the best option for your project.

Whichever grout you decide to use, Quikspray, Inc. has a grout pump that can help you get the job done. Contact us today to learn more about our pumps, tell us about your needs, and get expert recommendations for your product match.