Whether you’re working with thin materials that need a delicate touch or tackling the challenge of re-hydrating materials that have settled, the right approach to mixing is critical for maintaining consistency and quality in your projects. Mixing efficiently, especially when dealing with both small and large batches, or when required to mix for extended periods, can significantly impact the outcome of your work. In this post, we’ll explore expert strategies for mixing and remixing materials effectively using Quikspray’s Post Mixers, designed to handle a variety of needs with precision and ease.

Whether you’re working with thin materials that need a delicate touch or tackling the challenge of re-hydrating materials that have settled, the right approach to mixing is critical for maintaining consistency and quality in your projects. Mixing efficiently, especially when dealing with both small and large batches, or when required to mix for extended periods, can significantly impact the outcome of your work. In this post, we’ll explore expert strategies for mixing and remixing materials effectively using Quikspray’s Post Mixers, designed to handle a variety of needs with precision and ease.

Understanding the Mixing Process

Mixing materials, whether creating a new batch or reinvigorating an old one, is foundational in many industries, from construction and painting to food processing and pharmaceuticals. The goal is always the same: achieve a homogeneous mixture where all components are evenly distributed, ensuring consistent texture and functionality.

Mixing Thin Material

Thin materials, such as certain types of paint, sealants, or chemical agents, require careful handling to avoid over-mixing which can lead to air entrapment or separation of components. Here’s how to get it right:

Use the Right Tool: Equip yourself with a mixer that allows for adjustable speeds. Quikspray’s Post Mixer comes with variable speed control, enabling you to match the speed to the viscosity of the material, preventing splashing and air incorporation.

Gradual Addition: When adding powders or additives into thin liquids, do it gradually and on low speed to ensure better dispersion and integration of materials.

Re-hydrating Material

Sometimes materials settle or separate, especially if stored over long periods. Re-hydrating or remixing these materials requires not just reintegrating separated components but ensuring the revived mixture meets original specifications.

Start Slow: Begin at a slow speed to gather the settled materials from the bottom without creating a vortex.

Incrementally Increase Speed: Once the material starts to blend, gradually increase the speed to fully integrate all components.

Consistent Monitoring: Keep an eye on the consistency and make adjustments to speed as necessary. The visual cues will guide you to when the material has regained its intended texture.

Handling Small to Large Batches

Different batch sizes pose unique challenges. Small batches need precision to avoid over-mixing, while large batches require equipment that can deliver consistent power over a larger volume.

Small Batches: Use mixers like the Quikspray Post Mixer that can accommodate smaller containers without sacrificing control or efficiency.

Large Batches: Ensure the mixer’s motor is powerful enough to handle significant volumes without overheating. Quikspray mixers are built to maintain performance regardless of batch size.

Mixing for Long Periods

Some materials need extended mixing to achieve the right properties. Here’s how to handle long mix times without compromising on quality:

Durable Equipment: Choose a mixer that is designed for endurance. Quikspray’s mixers are robust and built to run for prolonged periods without overheating or wearing down.

Oversee the Process: Continuously monitor the mix to ensure that no changes in texture or consistency occur over time.

Regular Maintenance: Keep your equipment in top condition with regular maintenance checks, especially when running it for long cycles.

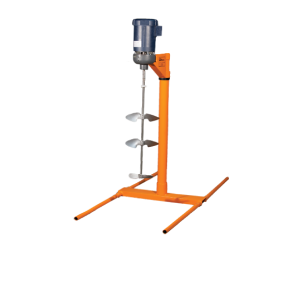

Get a Quote on Quikspray’s Post Mixers

Mixing and remixing materials effectively requires understanding the unique characteristics of your materials and the challenges they present. Quikspray’s Post Mixers are designed with versatility and durability in mind, perfect for achieving optimal results whether you’re working with delicate, thin materials, re-hydrating old batches, handling variable batch sizes, or needing sustained operation. For anyone looking to enhance their mixing processes, these mixers represent an invaluable asset.

Embrace the efficiency of Quikspray’s solutions and ensure that your materials are mixed right every time. Check out our range of Post Mixers and find the perfect match for your specific needs.