Choosing the right applicator spray gun is crucial for ensuring the quality and efficiency of your projects, whether you’re working in construction, automotive refinishing, or any other field requiring precise material application. Today, we’ll guide you through selecting the perfect spray gun to meet your needs, focusing on three main types offered by Quikspray: the Single Jet, Multi-Jet, and Shotcrete guns, each available with different nozzle options such as rubber cap, rubber orifice, or stainless steel.

Choosing the right applicator spray gun is crucial for ensuring the quality and efficiency of your projects, whether you’re working in construction, automotive refinishing, or any other field requiring precise material application. Today, we’ll guide you through selecting the perfect spray gun to meet your needs, focusing on three main types offered by Quikspray: the Single Jet, Multi-Jet, and Shotcrete guns, each available with different nozzle options such as rubber cap, rubber orifice, or stainless steel.

Understanding Your Project Requirements

Before diving into the specifics of each spray gun type, consider what your projects demand:

- Material Type: What type of materials will you be spraying? Different viscosities and compositions might require different types of spray guns and nozzles.

- Project Size: Are you working on large-scale industrial projects or smaller, detailed work?

- Desired Finish: What finish quality do you need? Different spray guns can offer variations in finish smoothness and thickness.

Types of Spray Guns and Their Best Uses

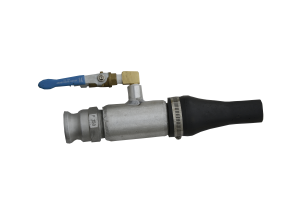

- Single Jet Spray Gun Ideal for detailed work and smaller scale projects, the Single Jet Spray Gun offers precision with a simple, straightforward design. It’s perfect for applications where control and accuracy are paramount.

- Best for: Automotive touch-ups, furniture finishing, and other fine work.

- Nozzle Options:

- Rubber Cap: Good for more viscous materials, offering a clean, controlled spray.

- Stainless Steel Nozzle: Best for thinner, more abrasive materials that require a sharper, more precise spray.

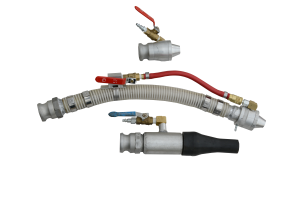

- Multi-Jet Spray Gun When coverage and speed are necessary without sacrificing quality, the Multi-Jet Spray Gun stepsup. This gun is designed to handle multiple streams of material, making it ideal for larger areas needing con

sistent coverage.

sistent coverage.

- Best for: Large automotive parts, big furniture pieces, or extensive surface areas in construction.

- Nozzle Options:

- Rubber Orifice: Offers a softer spray pattern, ideal for delicate materials that need gentle handling.

- Stainless Steel Nozzle: Provides durability and precision, suitable for heavy-duty materials and extensive usage.

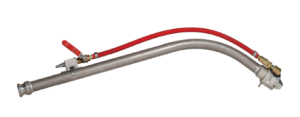

- Shotcrete Spray Gun For the toughest of projects, particularly in construction and heavy industrial app

lications, the Shotcrete Spray Gun is designed to handle robust materials like concrete. It’s built for high-volume, high-thickness applications.

lications, the Shotcrete Spray Gun is designed to handle robust materials like concrete. It’s built for high-volume, high-thickness applications.

- Best for: Constructing walls, creating large sculptures, or any project requiring thick layers of material.

- Nozzle Options:

- Rubber Cap: Helps manage the flow and reduces clogging with sticky or clumpy materials.

- Stainless Steel Nozzle: Ensures longevity and withstands the abrasive nature of materials like concrete and mortar.

Choosing the Right Nozzle

The nozzle is a critical component of your spray gun that can dramatically affect the outcome of your project. Here’s how to choose:

- Material Compatibility: Ensure the nozzle material is compatible with what you’re spraying to avoid wear and tear or chemical reactions.

- Spray Pattern and Width: Consider the size and shape of the area you need to cover. Different nozzles offer different spray patterns and widths.

- Cleaning and Maintenance: Some nozzles are easier to clean and maintain than others. If you switch materials often, consider a nozzle that cleans easily.

Quikspray Can Help You Choose the Right Applicator Spray Gun

Selecting the right applicator spray gun and nozzle can make a significant difference in the efficiency and quality of your work. Quikspray’s range of Single Jet, Multi-Jet, and Shotcrete spray guns provides options for various needs and applications, ensuring you always have the right tool for the job. By understanding your project requirements and the specific features of each spray gun type and nozzle option, you can choose the best spray gun for your needs, leading to better finishes and more successful projects.