When it comes to spraying cementitious materials, choosing the right spray gun can make a noticeable difference in productivity, material finish, and overall job performance. At Quikspray®, we offer a variety of spray gun sizes and nozzle configurations designed to handle everything from fine texture coatings to high-output shotcrete applications. This guide breaks down the key differences so you can confidently select the best spray gun for your specific job.

productivity, material finish, and overall job performance. At Quikspray®, we offer a variety of spray gun sizes and nozzle configurations designed to handle everything from fine texture coatings to high-output shotcrete applications. This guide breaks down the key differences so you can confidently select the best spray gun for your specific job.

Spray Gun Sizes Explained

Quikspray® spray guns are available in the following sizes:

- 1” Spray Gun – Ideal for lower-output applications such as fine texture and thin coatings. Offers excellent control and reduced material volume.

- 1.25” Spray Gun – A versatile middle-ground option commonly used for stucco, EIFS, fireproofing, and decorative finishes.

- 1.50” Spray Gun – Designed for higher production spraying, broader coverage, thicker materials like repair mortars, grout, epoxy grout, and pool plasters.

- 2” Shotcrete Spray Gun – Built specifically for high-volume shotcrete and structural concrete applications where maximum material flow is required.

Choosing the right size depends on material thickness, aggregate size, and desired production rate.

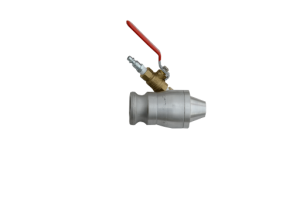

Single Jet vs. Multi Jet Spray Guns

One of the most important decisions is whether to use a single jet or multi jet spray gun.

Single Jet Spray Guns

Single jet guns deliver material through one central opening, producing a more focused spray pattern. These are often preferred for texture work and applications requiring precise placement.

Single Jet Options Include:

- Texture Nozzle – Available with or without rubber orifices. Great for controlled texture patterns and fine finishes.

- Rubber Cap (Single Jet) – Helps reduce wear and provides a softer spray impact for certain materials.

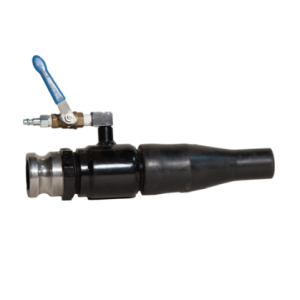

Multi Jet Spray Guns

Multi jet guns split the material flow into multiple streams, allowing for better atomization and more even coverage. These are ideal for higher-output applications and thicker materials.

Multi Jet Options Include:

- Rubber Cap (Multi Jet) – Durable and impact-resistant, commonly used in demanding spray environments.

- Rubber Orifice – Offers flexibility and wear resistance while maintaining consistent spray patterns.

- Stainless Steel Nozzle – Designed for long service life and abrasive materials where durability is critical.

Shotcrete Spray Gun Option

For large-scale concrete placement, Quikspray® offers a dedicated 2” shotcrete spray gun. This gun is engineered to handle high volumes, larger aggregate, and the pressures associated with shotcrete work. It’s the preferred option for structural applications, slope stabilization, pools, and concrete reinforcement projects.

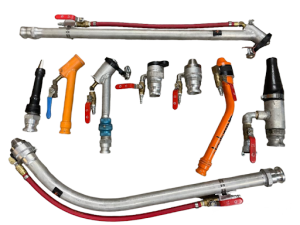

Custom Spray Gun Options Built for Real-World Jobs

Not every jobsite is the same, which is why Quikspray® offers custom spray gun configurations designed to solve unique access, reach, and maneuverability challenges. If a standard spray gun doesn’t fit your application, we can build one that does.

Custom Pole Lengths

One of the most common customizations is spray gun pole length. Depending on your needs, we can manufacture spray guns with:

- Short poles as compact as 12 inches for tight spaces, detail work, or close-range spraying

- Extended poles up to 6 feet long for ceilings, high walls, or areas where added reach improves safety and efficiency

Custom pole lengths help reduce operator fatigue while improving spray accuracy in hard-to-reach locations.

Nozzle-Only Spray Gun Option

For extremely confined or obstructed areas, Quikspray® offers a nozzle-only spray gun configuration.

This setup removes the traditional aluminum pole entirely, allowing operators to position the nozzle precisely

where a standard spray gun simply won’t fit.

where a standard spray gun simply won’t fit.

This option is ideal for:

- Tight cavities

- Structural repairs

- Retrofit or remediation work

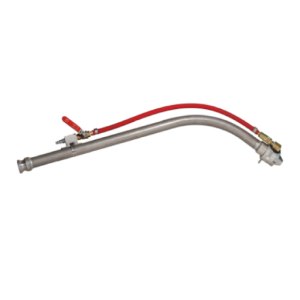

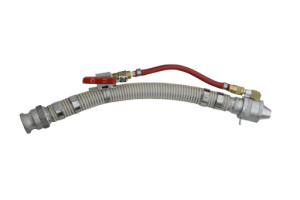

Flexible Hose Spray Gun Designs

In addition to rigid aluminum poles, we’ve also manufactured custom spray guns

featuring flexible hose sections in place of a solid pole. This design allows the spray gun to bend around obstacles while maintaining proper material flow and control.

Flexible spray gun setups are especially useful when working around:

- Rebar and formwork

- Irregular surfaces

- Complex structural layouts

Built to Match Your Application

Whether you need extended reach, compact access, or a completely custom configuration, Quikspray® works directly with contractors to build spray guns that match the job—not the other way around. If you have a unique spraying challenge,

chances are we’ve already built a solution for something similar.

chances are we’ve already built a solution for something similar.

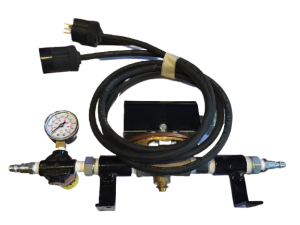

Spray Gun Accessories for Added Control

To enhance usability and operator control, Quikspray® spray guns can be paired with key accessories, including:

- ITT Switch – Allows the operator to easily control material flow at the nozzle, improving efficiency and r

educing waste. - Pneumatic Slide Valve Control – Provides precise on/off control of material flow, especially useful for high-production or stop-and-start applications.

These accessories help improve safety, consistency, and overall jobsite performance.

Choosing the Right Setup

The best spray gun setup depends on:

- Material type and aggregate size

- Desired finish or texture

- Required production rate

- Operator preference and jobsite conditions

If you’re unsure which spray gun or nozzle configuration is right for your application, the Quikspray® team is always available to help guide you toward the most effective solution.